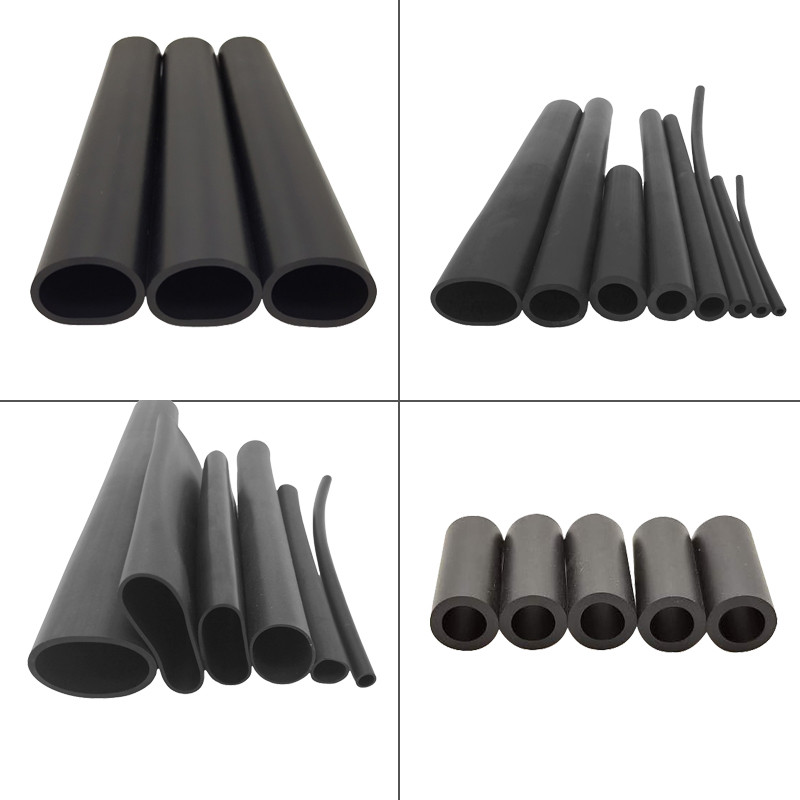

The Ultimate Guide to Choosing Rubber Tubing: What You Need to Know!

Rubber tubing is an essential component used across countless industries, from automotive to food, from home appliances to advanced electronics. With so many materials, specifications, and applications to consider, choosing the right rubber tubing can be overwhelming. This comprehensive guide will help you navigate the key considerations and confidently select the best rubber tubing for your needs.

What is Rubber Tubing?

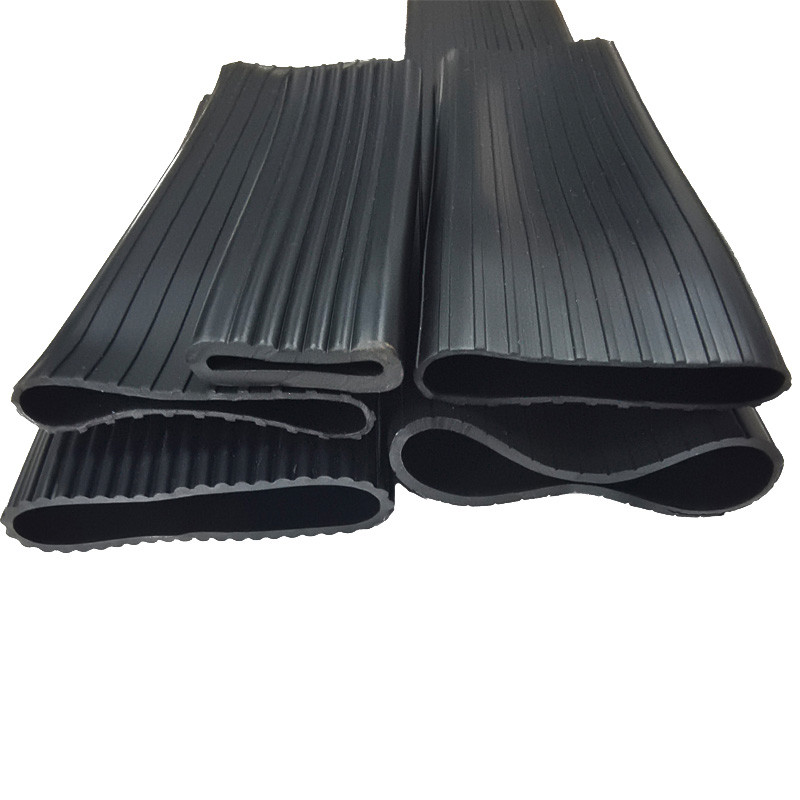

Rubber tubing refers to flexible hollow cylinders made from natural or synthetic rubber compounds. It is commonly used to transport liquids, gases, or protect wires in harsh environments. The material properties of rubber provide elasticity, chemical resistance, weatherproofing, and thermal insulation.

Common Rubber Tubing Materials and Their Applications

| Material | Features | Ideal Applications |

|---|---|---|

| EPDM | UV and ozone resistant, flexible, heat-resistant | Automotive, outdoor sealing |

| NBR (Nitrile) | Oil-resistant, durable, economical | Fuel systems, machinery |

| Silicone | Extreme temperature resistance, food-grade options | Medical, food processing |

| Neoprene | Moderate resistance to oil and weather | Industrial, refrigeration |

| FKM (Viton®) | Exceptional chemical and temperature resistance | Aerospace, aggressive chemicals |

Key Factors to Consider When Choosing Rubber Tubing

- Application Environment: Indoor or outdoor? Exposed to oil, UV, ozone, chemicals?

- Operating Temperature: Choose materials that can withstand your process's heat/cold range.

- Flexibility and Bend Radius: Essential for applications requiring frequent movement or tight installation spaces.

- Regulatory Compliance: FDA-grade for food and medical use; RoHS/REACH compliance for electronics.

- Customization Needs: Size (ID/OD), wall thickness, color, hardness, reinforcement (e.g., braiding).

At RESRUB, we specialize in custom-manufacturing rubber tubing tailored to your specifications. Whether you require braided rubber tubing for PC liquid cooling, high-durability tubes for industrial machinery, or FDA-compliant options, we provide engineered solutions with strict quality control.

Why Choose RESRUB Rubber Tubing?

RESRUB (Xingfeiyu Rubber & Plastic Products Co., Ltd.) is an ISO9001:2015 and IATF16949:2016 certified manufacturer based in Dongguan, China. With over a decade of experience, our 5,000m² factory supports high-volume extrusion (60 million meters/year) and molded rubber parts.

Key Advantages:

- Own R&D lab and testing equipment

- Full range of materials (EPDM, NBR, Silicone, FKM, TPE, and more)

- Custom dimensions, durometer, and braiding available

- Fast turnaround for samples and production

- Serving global industries: automotive, electronics, PC cooling, appliances

Visit our About Us page to learn more.

Typical Industry Applications

- Automotive: windshield wiper spray pipe, sealing tubing, door seals

- Electronics & PC Cooling: Low-evaporation tubing for liquid cooling systems

- Medical & Food: Sanitary silicone tubing

- Dishwasher & Home Appliance: High-heat resistant sealing tubes

How to Request a Quote or Sample

- Send us your drawing/specification or application scenario

- Choose material and performance requirements

- Receive a custom quotation and lead time

- Get samples for testing (available for qualified projects)

Contact our team today at info@resrub.com to discuss your rubber tubing needs.

Final Thoughts

Choosing the right rubber tubing can directly impact the efficiency, durability, and safety of your product or system. With a clear understanding of materials, performance requirements, and manufacturing capabilities, you can make informed decisions. Trust an experienced partner like RESRUB to provide the quality and customization your business needs.