Are you looking for a reliable manufacturer of rubber seals and rubber tube products

We can quickly provide customers with market analysis, technical support and customized services.

Get in touch

We use advanced 3D modeling and simulation technology to create functional and aesthetically pleasing designs that are sustainable and environmentally friendly.

The prototyping process uses rapid prototyping technology to shorten the cycle and improve efficiency, and conveniently submits proofing applications through an online platform to achieve efficient communication.

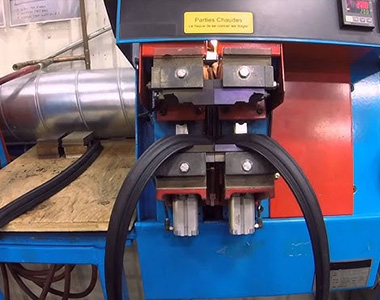

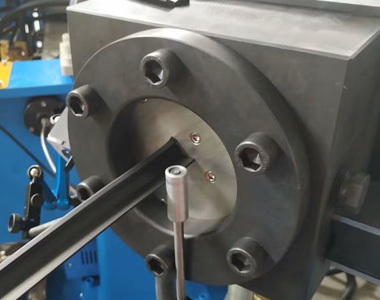

We use highly automated and digitalized production lines to flexibly respond to orders of different sizes, and can quickly adjust from small batches to large batches to meet market demand.

Mold design and optimization, comprehensive maintenance, technical training, etc., a dedicated maintenance team, regular equipment maintenance, reduce failure rates, and extend equipment life.

We understand that choosing the right product for your industry is critical. That’s why we invite you to contact us. Whatever your goals, Linenwind will help you achieve them.

Learn MoreWe have a strong team that works closely with customers to meet market challenges and effectively meet specific needs. Our slogan is "Economical, Time-Saving, and Effortless Management" to win customer trust in your industry.

Start Customizing